Preparing Metal Stud Walls For Masonry

Metal Stud Walls & Masonry

Recently I wrote an article, Metal Studs with Densglass Sheating and Foam Board Insulation, which showed how we framed an exterior wall with metal studs then applied Densglass Exterior Sheathing followed by a layer of foam board insulation. This was all in preparation for a final layer of exterior masonry brick facade.

Recently I wrote an article, Metal Studs with Densglass Sheating and Foam Board Insulation, which showed how we framed an exterior wall with metal studs then applied Densglass Exterior Sheathing followed by a layer of foam board insulation. This was all in preparation for a final layer of exterior masonry brick facade.

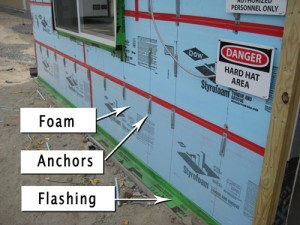

Today I’d like to further expand on the previous article and show some of the preparation that’s been done prior to the mason installing the final layer of bricks. The masons showed up this week to install the lower wall flashing, window and door flashing and the brick anchors.

Wall Flashing

The mason is using Perm-A-Barrier Wall Flashing by Grace to flash the base of the wall. Perm-A-Barrier is a self-adhesive, rubberized asphalt/polyethylene flashing tape for cavity wall applications. I really like this product because it won’t react with the concrete brick shelf so it will last for years and keep the water out of the wall base.

Window and Door Flashing

The mason is also using the Grace Perm-A-Barrier around all the windows and doors. It’s really easy to install this type of self-adhesive flashing and it can be done without nails, stapples or screws which means fewer places for leaks!

Brick Anchors

Vertically stacked brick on a brick shelf needs to be “tied” back to the building to prevent out of plane movement. For our application the mason has selected a brick anchor that gets screwed directly into the metal studs. The anchor has “teeth” that penetrate the foam insulation and Densglass sheathing. Then the anchors are secured to the wall with self-tapping screws. As the brick is stacked up anchors will be installed in the mortar and attached to the anchors in the wall.

Proper Preparation

By properly preparing this wall with good insulation, sealed joints, proper flashing and adequate anchors we’re insuring that this new masonry wall with last for years without any problems from the environment. If you’re building masonry walls take the time to insulation and flash correctly for a long lasting high performance wall system.

This self adhesive flashing is new to me. It sounds great and we will sure check it out for The Stone House project.

What would be the best way to brick / stone outside wall if there is not enough ledger room on the foundation. Structure has existing metal exterior walls and finished interior walls.

Thanks

C Woods – You can build a brick shelf out of steel angle shapes. I would get them hot-dip galvanized and then attach them to the building at grade level. The other option is to pour a small footing to carry the masonry load.