Basement Vapor Barrier For Basement Insulation

Bad Basement Insulation Detail

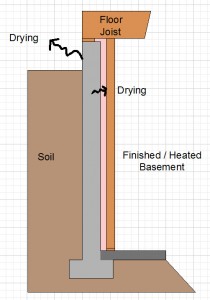

One of the worst basement insulation details that we see on a regular basis involves framed walls adjacent to concrete foundation walls. The cavities of the framed walls are filled with fiberglass insulation and a vapor barrier is installed between the studs and drywall.

One of the worst basement insulation details that we see on a regular basis involves framed walls adjacent to concrete foundation walls. The cavities of the framed walls are filled with fiberglass insulation and a vapor barrier is installed between the studs and drywall.

This basement insulation detail is a really bad idea. As the concrete dries and gives off the water vapor it get’s trapped between the concrete wall and the vapor barrier. This causes the fiberglass insulation to become saturated with water. Water laden fiberglass is extremely inefficient and very prone to mold growth.

As you can imagine once the fiberglass becomes soaked in water it’s nearly impossible for it to dry out. The fiberglass must be completely removed and disposed of. It’s also very likely that mold will have grown on all the studs, drywall and floor joist framing above.

Hi Todd.

Not sure if you replied but i can’t find the page i posted my question on.

I was interested in following your article above on how to insulate the basement and vapor barriers, etc.I noticed how you said frame infront of the foam and to leave a one inch space between for air flow.

How do i help to keep the foam attached to the wall?? I was going to use an adhesive and then frame up against to keep it in place, but the air space you said was better.

Can i use wall anchors for the foam too?? I was concerned if they work on my old basement wall.

Also, my township requires horizontal and vertical fireblocking. How do i incorporate this into your instructions and diagram above and still be in code??

Note: i am not covering or finishing my ceiling. my head height is too low so i will just leave it open and paint instead.

Thanks for all your help.

Rob A.

@ Rob – We typically use an adhesive specifically made for foam board. The key is to put the adhesive on the foam and let it sit for a few mins before you apply to the wall. That allows a skim to form on the glue and it sticks better to the wall. I’m not sure the fire blocking is applicable in your situation. It’s typically applicable with balloon framing which you will not have in this situation. It’s best to check with your building inspector ahead of time and find out what he/she wants. Good luck.

Thanks Todd.

I’ll be using the blue foam and adhering the silver side on to the wall and blue side facing into the room, correct??

My township website shows a diagram of the fire blocking on a finished basement wall, and uses horizontal and vertical blocking. it says they require vertical fire blocking at 10ft intervals.

Seems unnecessary to me too, but i’ll need to talk to them first and explain what i’ll be doing then see what they say.

Thanks,

Rob A.

@ Rob – What foam product are you using? Without knowing which product it’s hard to say which face goes towards the concrete.

Hi Todd.

it’s the SUPER TUFF-R 1 1/2 In. 4 x 8 Polyisocyanurate Rigid Foam Insulation. it’s silver on one side and blue on the other.

Is this the best to use??

@ Rob – You have it correct. The product you are using is probably the top of the line…but certainly will do the job!

the blue side faces? in to the wall?

which product are you using? some of it is blue on both sides.

Hi Todd

I live in southern Missouri, cold but not extreme, I’d like to cover the poured basement walls. I’m thinking about glueing foamboard between 2×2 furring strips and paneling over it. Any reason not to?. I don’t think I need the additioanl insulation value a fiberglass-inside 2-4 stud wall would provide. Ceiling is insulated with plastic covered fiberglass and will be covered with drywall. Walls have been uncovered for 15 years so they are as dry as they will be. We use a de-humidifer ithe room. Most of wall area is completely below grade. Also if I can use this set up, do I need a platic vapor barrier under paneling? What type of formaldehyde free foamboard do you redommend? Thanks for your advice. G. Brewer

@ Gary – I would glue the foam board directly to the concrete. Then place your furring over the foam and secure it through the foam into the concrete. Either that or frame a wall in front of the foam. Be sure to tape the seams well. No need for a vapor barrier. Good luck!

todd,

my basement foundations walls were very poorly poured in 1952 w many honeycombs, air pockets, and poor adhesion between poors.when we would get as little as a 1/4 inch of rain i had water running across the floors. for this problem i have installed a complete interior seepage drain system in my basement that also has a lip that sits above the floor against wall that collects any seepage water off walls.i corrected any outdoor water problems-downspouts,improperly sloped concrete,terrain,etc. i have also applied hydraulic cement after chipping out concrete in any spots on walls that still had visible water seepage,i then applied dry lock paint to these areas. this has taken care of any visible moisture on walls or floors after heavy rains–(recently 3″)dry is nice. i have also put in a radon mitigation system that is sucking air from under my basement slab through the seepage drain system so any moist air is being removed off of foundation wall(the design was to remove radon but by incorporating it with the seepage system im also pulling air from the moist foundation wall through the earlier mentioned lip against wall). with all this being said i’m currently furring out the walls staying 6″ off foundation wall,treated lumber for bottom plate,fiberglass insulation in void between floor joists on sill plate against ribbon joist,below this foam board insulation-to prevent mold- from top of foundation wall 4′ down-not the whole stud space- flush with drywall face of stud. does all this sound ok and should i install vapor barrier between foam insulation and drywall. i know this sounds like a lot of information but i figured the more descriptive the better. thank you for your assistance in this matter.

chris

Sounds like you’ve been busy fixing the real problems which is good! I would recommend you read this article:

http://www.homeconstructionimprovement.com/how-to-insulate-basement-walls/

It shows how I recommend you insulate the basement walls. I really don’t recommend only doing 4′ as you propose.

I would also recommend you read the following article on the rim joist insulation:

http://www.homeconstructionimprovement.com/rim-joist-insulation-insulating-options/

Good luck.

Reading your article has made me re-think my approach to insulating my basement walls. I live in Upstate NY, where the Winters are brutally cold. My 5-year old house has block basement walls.

I decided to experiment with one wall and installed the DOW 2″ rigid foam board, and am building a standard 2×4 wall as well. I intended to fill it with R-13 fiberglass insulation.

One question, however. I am not sure if I should use a faced insulation or not. According to your article, it seems unnecesary (since I am using 2″ foam), however I cannot find any rolls of R-13 unfaced fiberglass at the box stores! I can find R-13 pre-cut batts, but they are twice the price and will result in about 6″ of waste per batt. Any suggestions? Alternative include (1) using R-19 for 2×6 walls and compressing it (bad), or using R-13 faced rolls.

Many thanks for your insightful article.

-Todd M

@ Todd M – Thanks for visiting the site. The vapor barrier won’t do any harm in your situation. If that’s the cheapest product available then I say go with it. Good luck.

Hello Todd,

I am having my basement redone after a fire. The basement was previously finished with chip board paneling partially over framing and partially directly on the concrete. We will be using dry wall. The building contractor I am using for the rebuild has framed out the wall with TYVEX behind it. He says that it’s not necessary to put in insulation behind the dry wall because the air space and the soil around the foundation will provide all the insulation needed. The basement has never had moisture on any of the walls, but it is always colder in the winter and summer then the rest of the house. Is my contractor correct, or should I insist on insulation on the outside walls of the basement?

Thanks,

Greg M

@ Greg M – First off it partially depends on where you live. However, I would insulate it regardless if it were my home. Secondly, Tyvek will actually allow water vapor to move through it in one direction so technically the water vapor “could” move from the foundation to the framing depending on the side that is towards the framing. Frankly even a “dry” looking foundation was is extremely damp and full of moisture.

Todd great article, just ordered my rigid foam and materials to frame the basement out. I live in Northwestern Indiana and will be finishing my basement as to your article. As an extra form of protection we used Epoxy on all the joints and used Zinsser waterproofing paint LX. We will be using 1 1/2″ foam. I am unclear about a few things: How much adhesive should be used per 4×8 sheet of pink foam? Also for the pink foam which side goes towards the concrete?

Lastly we have had a moisture problem on the Rim Joists where air seems to be getting trapped between the Batt Insulation and the Rim Joist creating dampness. Would this work well for the Rim Joist? We are looking for the best solution before we get to the drywall portion of the job. Happy New Year!

@ Alex – Thank for the compliment.

The amount of adhesive really isn’t all that important. We typically install a bead every 12″ or so. Apply it to the foam, let it stand for 5 mins until it skims over then apply to the wall. Foam board works great on rim joists. Use 2″ minimum and seal it in place with spray foam. Good luck.

Todd,

I have glued 2″ Foamular 250 to my concrete walls and taped the seams with Tyvek. I have built the 2×4 walls with 1/2″ to 1″ gap between the studs and foam. My plan is to use the encapsulate fiberglass insulation.(I prefer working with it). Is there a problem in using totally encapsulated fiberglass?

Thanks,

Nick

@ Nick – We’ve never used it so I can’t give an opinion. I think it should work fine after what you’ve already done. Best of luck.

I have read all of your articles on foam board and vapor movement, but do not understand how the foam board approach solves the problem of trapped vapor. If the foam board is glued tightly to the wall (avoiding the air gap), the water vapor still needs to go somewhere. Why would it not just penetrate the foam board and cause the same problem as insulation? It seems to me that the foam board is as much of a vapor barrier as foil-backed insulation, which everyone agrees is a problem.

Can you help clarify? (I have a below-grade basement (100-year-old house) that is freezing cold in the winter, so I am trying to insulate in some way. I also have some minor seepage that comes through the wall during heavy rains.)

@ Paul – Properly installed foam board insulation can create a very effective vapor barrier. Foam board also has the benefit of not promoting mold growth like fiberglass. There are two issues that you’re trying to deal with. First of all the foundation walls are FULL of water and we want to keep that from getting to the framing and wallboard. Secondly we want to keep any moisture from the finished space from passing through the wall and hitting a cold surface where it could condense into liquid form and saturate the framing and wall finishes. Closed cell foam insulation products provide a great barrier to vapor movement. I hope this helps.

Todd,

I have 40 year old pored concrete walls that have never had a water problem in turns of seepage, though have scaled off the original paint job considerably in some areas. Should they be repainted before gluing the foam board to them?

Also, is a combination of foam board and batt insulation the way to go in insulating the areas above the sill plate? I can’t tell you how many different opinions I’ve read on this.

Thanks,

Bob

@ Bob – In both situations it’s all about a cost issue. Ideally we’d all insulate basements with spray foam if money were no issue. The idea of using both foam board and fiberglass is a more economical hybrid. Having said that I like to see a minimum of 2″ of foam board on the rim joist, spray foamed in place….followed by additional fiberglass to supplement. Best of luck.

I have been searching endlessly and i believe @todd explained this finally for me. Here is what i am doing, I’m sorry if this scenario has been explained somewhere else.

I have a 4 year old house (southern Ontario) it has a delta membrane on the outside foundation… builder has put up R12 fiberglass batts about 4-5 ft down on the concrete wall. I want to install durafoam EPS not XPS directly (PL Premium)against lower half of concrete wall. Tuck tape into existing upper half. Then put dricore down, add metal framing on top. I want to use XPS or EPS directly on the rim joists and seal around with canned spray foam then add roxul insulation behind everything. Then no more vapour barrier just drywall it up.

I know this is not code, but can you foresee there being problems with this hybrid insulation method? thanks

Paul – First off I would never use EPS in a basement, it’s an open cell foam and it can/will collect/hold water. Secondly, I would remove the existing fiberglass insulation. You need foam from the top to bottom on the walls.

I am using EPS rigid 2″ durafoam with the foil backer (it is a closed cell foam) has an R value of 7.5

http://www.plastifab.com/homeowners/buildinghome/plastispan_duro/plastispan_durofoam.html

Paul,

EPS is NOT a closed cell foam board….it’s made with closed cell foam balls…not the same thing.

http://www.homeconstructionimprovement.com/foam-board-insulation-values/

I would NOT recommend that in a basement.

Hi Paul

I was following your post as I need to insulate my basement (block foundation) and was thinking of using Durofoam 1.5 inch (R 5.6), and I was wondering if Durofoam is what you ended up using for your basement. I’m located in the Ottawa, ON area.

Tanya

Tanya – I responded to your email. Durofoam is an XPS foam, which I do not recommend in basements. It consists of closed cell balls of foam that are compressed together, but the “matrix” of balls is not truly closed cell.

Good luck.

Hi Todd,

I have an interesting question. We’re all worried about moisture in the basement and getting into the insulation. I was thinking of putting a layer of rubber tar on the inside of the basement foundation and then putting the foam board up. It comes in 5 gallon buckets and you just roll it on. Theoretically that should keep all vapor from coming into the inside of my house. I have a layer of tar on the outside of my foundation for waterproofing when we built the house. The only thing I’m worried about is does the concrete have to breath, and maybe all that tar might make it too water/airtight. What do you think. I thought it would be a good idea. – Erik

@ Erik – In theory it might work but most all tar based foundation products are damp-proofing and not really water-proofing. What that means is it helps keep most of the water out but it won’t keep it all out. Plus, if it cracks, it won’t likely stretch enough over that crack and it will crack itself. The other thing you might consider is the VOC’s and off gassing. That stuff typically smells horrible and might not be a great solution inside. Just my thoughts…..

Todd,

Framing poured basement walls in a new house in Delaware. I too am concerned about creating a mold situation. I stapled 15 mil plastic wrap on the inside of the 2 x 4 walls prior to putting the walls in place. Then plan on using R13 basement Insulation then cover with 1/2 sheet rock. I have a floating slab which doesn’t contact the walls and it all drains into the sump pump. Held the 2×4 walls 1″ off the Basement wall. My question is should I cut the Plastic off and discard it? Will I trap moisture between the plastic and the insulation? Should I just let the walls breath?

Joe – The plastic is a problem along with the approach. The concrete wall will be cold and damp. If you place the plastic and any water vapor gets into the wall cavity it’s going to condensate against the cold plastic surface. If you remove the plastic, water vapor can really go nuts in two directions, drying of the concrete in the summer can move water towards the fiberglass and in the winter it will go the other direction. You REALLY should consider using foam.

Hey Todd, great article. I have a dilemma–just moved into a newly-constructed home and we want to finish the basement. The basement walls are fully insulated with the foil-faced fiberglass blanket insulation. I’m unsure whether to just frame my wall in front and cover w/ .5″ drywall, or rip it all down in favor of the foam board system above–it seems that buildingscience dot com would recommend the latter option, but wanted to see your thoughts-we’re in MD if that matters.

thanks

john

@ John – Thanks! I hate to say it but if it were my home I wouldn’t leave it that way. Just too risky with mold problems.

Todd,

Thanks for the advice on 12/31 about glueing the foamboard to the basement wall and screwing furring strips over the top of the board. A much better approach for sealing the wall. For southern Missouri do I need 1 1/2 inch board or will 3/4 inch serve the purpose of moisture barrier and temperature control? I’m covering the foamboard wiht paneling.

thanks again, Gary

@ Gary – Most literature that I’ve read says that 1-1/2 to 2 inches is the minimum to create an effective vapor barrier. Being in Southern Missouri I’m not really sure how cold your weather gets. You might be able to use foam plus a vapor barrier…but if that foam get’s cool on the finished side it might promote condensation of any moisture that get’s past the paneling. I guess what I’m saying is I’m just not sure. Good luck.

I called the manufacture of DURA FOAM (Plasti Fab in Ont. Ca.) they recomended that I use there 2″ foam board that has a green and a foil side. They said that the foil side should face toward the room to reflect the heat back into the room and the green side against the concrete wall.

do I have to use foam board that is covered with foil or plastic or can I just use standard 2″ foam board (ei. not coated) ?

@ Paul – If you use 2″ of foam it is thick enough to create a vapor barrier. However, if you use a product with foil or plastic the vapor barrier is even better! As with anything….you get what you pay for :)

Todd – I have not found the two inch foam insulation with foil at any of the local suppliers (Lowes, Home Depot, Menards). Where can I find it? What company makes it?

It’s a DOW product and it’s typically sold at more traditional building supply / lumber yards that deal with commercial construction as well as residential.

Hi Todd:

To begin with, many thanks for offering your time and expertise to help those of us who lack the necessary training. I have some questions concerning insulating the interior surface of exterior concrete walls that have the same problem as basement walls.

I am purchasing a small, 600 sf, top floor, corner unit apartment in a concrete building that is presently under construction (top floor!!!??? I know, I know, but I cherish a quiet living environment). The apartment is located in the south-east corner of the building with other apartments to the north and west sides. The apartment has radiant heat flooring. Sorry, I don’t have the specs, but my understanding is that it is intended to maintain an interior temperature of 16 degrees C (61 F), but at what outside temperature, I don’t know yet. The outside temperature can vary from 40 degrees C (104 F)(normally 30 to 35 degrees C) in the summer to -40 degrees C (-40 F) (normally -8 to -20 degrees C) in the winter. There may be some insulation on the outside surface of the exterior walls and flat ceiling, but I’m not sure. I am not permitted to alter the outside surfaces of the exterior walls and flat ceiling. None of this would be a problem if it weren’t for the fact that I prefer a constant 25 degrees C (77 F) interior temperature. Thus, it could be said that my problem is self-inflicted.

It was when I read your article that I discovered the problem with condensation on cold interior surfaces and the ensuing mold problem. It seems to me, as you say (I think) that the solution is to add insulation to the interior surface of the concrete walls and flat ceiling so as to create a monolithic wall with a dew point somewhere in the interior of the concrete wall while ensuring that there are no air gaps between the concrete wall and insulation or between multiple layers of insulation. After creating such a monolithic wall, I would then construct a frame wall and install additional insulation. Assuming that my assumption regarding the nature of the problem and its solution is correct, I have some questions:

Question #1: Do I correctly understand the problem?

Question #2: Do I correctly understand the solution?

Question #3: You mentioned that you install an adhesive bead about every 12 inches on rigid foam insulation to bond it to a concrete wall. Is if permissible to cover the entire surface of the rigid foam insulation with adhesive in order to ensure that there are no air gaps between the concrete wall and the rigid foam insulation?

Question #4: Would it be best to bond multiple layers of rigid foam insulation to each other using an adhesive in order to avoid any air gaps?

Question #5: Will using “RadonSeal Deep-Penetrating Concrete Sealer” (http://www.radonseal.com) to seal the concrete in conjunction with using rigid foam insulation solve the moisture problem? To what level of certainty? (It is my understanding that painting a concrete wall with a water-proof paint will not work.)

Question #6: Will the solution for the concrete walls also work for the ceiling? It seems that it would, but hey, I am way out of my league here.

Question #7: You said that spray-in-place foam insulation is one of the best ways in which to insulate a basement wall, but it can be expensive. I’m thinking that since my apartment is only 600 sf, and I only have two exterior walls and a flat ceiling, perhaps the cost wouldn’t be prohibitive. I would greatly appreciate it if you would provide the construction details on the use of spary-in-place foam insulation to solve this problem.

If you need any additional information, please let me know. In March, I will have a chance to meet with the engineer who designed the building. I want to ask him for information regarding the capacity of the radiant heat flooring and the construction details of the exterior walls and flat ceiling.

Many thanks for your help.

Sincerely,

Dan

It’s hard to imagine anything passing through HD (high density)foam!If I use the foil covered and seal it well toward the foundation wall(concrete), will I require a vapour barrier after my studed and fibre insulate wall prior to installiing my dry wall? (pink or blue foam? in case I don’t go with the foil covered) Thank You!

@ Paul – There are two issues…moisture from the concrete….but also moisture from the finished space moving towards the wall and condensating on the surface of the foam.

Does this order for a well insulated the basement sound correct: Foundation wall, HD foam (covered with foil, plastic or not) , 1″ air gap, 2×4 fibre glass insulated studed wall, dry wall, primier and paint, living space! Thank you!

@ Paul – Depends on where you live..if you live in a really cold area….you really should consider 2 inches of foam.

Hi Tom,

I’ll soon be moving into an old farmhouse with a stone wall basement up to ground level, and then a concrete sill sitting on top of the stone wall (an addition in the 1920s after the original house burned down and the latest one was built). The floor is dirt.

Knowing that there will be gaps between the stone wall and the foam board, do you recommend I still trying to insulate this way? Mary

@ Mary – I would recommend spray foam for a stone foundation such as yours.

Hi Todd,

Great article.

I live in a house about 10 years old in MI. It has 90% below grade poured foundation without any water problems. It does have some sort of product sprayed on all the foundation walls by the builder that looks like a stuco of some sort, but I’m not sure.

Anyways, I was hoping to use 1″ rigid foam glued to the foundation for the moisture barrier, then 2×4 frame with fiberglass insulation, then vapour barrier and drywall. There is a drastic difference in cost with the thicker rigid foam.

Do you think my direction will work or should I spend the extra few hundred dollars for the 1.5″ and still use the vapour barrier?

Thanks again,

Rob

@ Rob H – I highly recommend you use the 1.5 inch foam.

how would you insulate a walkout basement that is block wall and has sides partially under grade,

thanks

]

mike

@ Mike Jones – Just the same way we’ve shown in our other articles. Block wall is really the same thing as a concrete wall.

Hello Todd… We live in Ontario, Canada. I am doing our basement over…have put 2″ foamboard and taped and sprayfoamed all gaps. Have studded the walls and because of sewer line have allowed for 5 1/2 inch insulation against the foam board. This bat insulation is from the pt baseboard and full height. My question is do I need to leave an airspace between the foam board and the bat insulation? Should we have a vapor barrier due to our cold winters? Thanks Marvin

@ Marvin – No air space is required. Because you’ve used 2 inches of foam i would skip any kind of vapor barrier.

The one inch gap is between the foam and studs but not necessary between the foam and fiberglass? Is that correct?

@ Vern – You are correct.

Hello Todd. House was built in 1957. Has poured walls. Bought the house about 5 years ago. Looks like they had a water problem at one time because there is metal flashing somewhat newly concreted into the edge of part of the basement floor along the basement wall. Also, similiar concrete without flashing along other edges. there are afew cracks in the wall that they have covered up with flashing and that plastic wallboard you see in bathrooms sometimes. We have never had any water in the basement. I wonder if the foam board style vapor barrier would work? And if so, do you think I can nail the composite decking into the edge?

Thanks

@ Dave – The foam board should work great. Not sure I know what your question is about the decking though? Can you be more specific?

Todd:

I live in Michigan and have started my basement project. I,ve applied 2″ foamboard to the poured walls, sealed it with sprayfoam on the tops and bottoms and either spray foamed or taped all seams depending on gaps. My rim joist is insulated with R-13 fiberglass. My intention is to install a floor system that allows an airgap between the slab and finished floor, and to build the walls on top of that leaving a 1/2 inch airgap between the studs and the foam. I’ll drywall the cieling too.

Do I need to insulate the stud walls? What about a vapor barrier between the stud walls and the foam? Any thing else I’m missing?

Many Thanks!

@ Rich – Sounds like you’re doing well so far. Couple things, one I really recommend you change that R13 and install foam on the rimjoist. Fiberglass doesn’t do well in that application and I bet it’s likely you’ve got moisture behind if you check. With 2 Inches of foam properly sealed there’s no need for a vapor barrier. The only issue is whether you want more than the R10 the 2 inches has given you.

Good luck.

Todd,

Good information here. We have an 8yr old home with unfinished basement. Walls are poured concrete ranging from 9’tall stepping down to a walkout. I understand your approach for insulating the complete walls but areas of the basement only have 4′ and 2′ concrete walls with the remaining height being wood framed. The builder of the home used unfaced fiberglass bat insulation within the stud cavity with an additional poly vapor barrier stapled over the framing and insulation. Question…Do we attach the 2″ foam to the concrete portion of the walls and leave the existing wood framed portion with insulation and vapor barrier as is? Obviously the wood framed exterior walls are above grade. I’m assuming the poly vapor barrier on the exterior framed walls needs to be somewhat air tight?…Tape the seams, etc….What mil poly do you just as being adequate for acting as a vapor barrier?

@ Bryan – Thanks for the compliment. Your house is built like many new homes today. Your assumptions are correct. Just be sure that you seal the foam to the poly vapor barrier well with tape. Also, just to be sure that your existing condition is ok, cut a small hole in the poly and check to be sure the fiberglass is dry. If it is, tape up the hole and proceed as you’ve indicated. Typically 6 mill poly is sufficient.

I have the same setup at my basement but was wondering about the framing. Instead of a stepped frame/drywall directly against the above grade portion, I wanted to go straight up from the floor. There will be a few inches of gap from the finished drywall to the poly & insulation on the above grade section. Is that an issue, or should I remove and re-tape the poly between the new drywall and framing?

Thanks,

Eric

Should be fine, having air behind that drywall is always a good thing :)

Thanks Todd. I’ll change out the R13 in favor of 2 inches of foam sealed with spray foam. Should I worry about moisture from inside the living space going out into the air gap?

What about the cieling? Basiclly when done I’ll have an air gap around the whole basement. Will that create any issues in the cieling cavity where the air can flow between the floor joists above? Should I insulate it or will that create other issues?

Thanks again for your expertise.

@ Rich – I wouldn’t worry about living space air getting into the air space. Frankly, a well primed layer of drywall acts as a vapor inhibitor which drastically slows the movement of water vapor but lets it breath at the same time. Unless you have a high moisture level after finishing the walls I wouldn’t worry about the ceiling area. If the moisture levels are high then you’ll want to use a dehumidifier.

Todd,

Clarify what you mean by seal the foam to the poly vapor barrier with tape? Do you mean at the point where the top portion of the concrete wall covered with the 2″ foam meets the poly vapor barrier covering the wood framed exterior wall? I assume the 2″ foam is only needed on the concrete portion of the basement walls.

Thanks

@ Bryan – You are correct.

Greetings Todd

Great info on doing basement walls. Could you answer a question i have? how do insulate the pockets were the floor joists meet the toe plate above the sill plate? or do you just leave it? I think the toe plate is resting on the top of the cement wall and the sill plate as well which is flush to the inside of the basement wall.

Thanks Doug

@ Doug – There are several approaches.

1. Spray Foam – Best solution but most expensive.

2. Foam Board – Great solution not as expensive, cut the pieces to fit loosely and then spray foam (Great Stuff) to seal.

3. Fiberglass Insulation – This is the bear minimum.

Todd,Thank you for your answers,One more question if you could? I do have some fiberglass between the joist already but there is no vapour barrier? i assume that this is not correct. Thanks Again, Doug

@ Doug – Have you taken a piece down and checked for moisture. Typically we see lots of moisture, frost and mold between fiberglass insulation and the rim joist. Without a vapor barrier the warmer, moist air get’s behind the fiberglass and condenses on the cold rim joist. That’s why we like using foam board.

Hi again Todd

I live in South Ontario, Ajax close to the lake. I have a poured concrete foundation (25 years old). I have decided to spray foam (2″ R-13) from above the sill plate in between the joist down to the concrete basement floor. The next step will be erecting a 2×4 studded wall parallel to the foam and insulating it with Rocsul Bats an R-15 (TOTAL R-13 + R-15 = R-28).

Two questions: Should I stud my wall first 2″ away from the concrete foundation then have the foam srayed in allowing no air gap between the back of the studs and the foundation ( which will also tie in the top plate of the stud wall to the joist-sill plate area) or spray foam first then build my stud wall ? both application will leave the stud cavity viod so that I can install a R-15 Rocsul insulation.(total R-28)

Second question: Either way do I require a Vapour barrier on the front of the studs toward (facing) the warm zone? Thank You in advance!

@ Paul – Question #1, I don’t think it matters either way. Question #2 no need for a vapor barrier in your application.

Todd

In your opinion in question #1 what would you do since nothing exist at this time but a bare wall?

@ Paul – Not sure I understand your question. I don’t think it matters if you frame before or after. I think your approach is solid and will create a very nice R value.

Sorry Todd I should have been more clear ! I want your opinion on whether you would spray foam the bare wall first then build your stud wall or would you build your styd wall then spray foam? Thank You!

@ Paul – That’s what I meant when I said it doesn’t really matter. Frankly your spray foam guys will probably be glad if you frame afterwards. Good luck.

Todd

Thank you for your time and advice. I was think the same thing about how difficult it would be applying foam around the studded wall, not to mention the header plate with all the cold/warm air ducting.

Just to recap, the finished wall will look like this:

Foundation wall, foam sprayed 2″ R-13, studded wall with cavity fill with Rocsul R-15, dry wall sheeting, primer & paint, which will equal a warm health basement . If this is correct work starts Friday!!!

@ Paul – Good luck! Send us some pictures and we’ll show everyone!!

Hey Todd we did the 1.5″ thick Rigid Foam on the walls and all concrete, we sealed off the seams. It made a HUGE difference in the temperature. We live in Northwest Indiana about 2 miles from Lake Michigan and its very cold out right now. We are going to have the Rim Joists spray Foamed with closed cell spray foam. We noticed since we put the Rigid Foam and increased our temp our Cold Water pipes are starting to condensate, and drip. We started framing, and also are putting in zones so we can control the heat/ac separate downstairs. We will have about 1300 of finished SQ. footage all drywalled. How do you suggest we handle the water pipes? Should we insulate them? Should we do anything different for the cold / hot water pipes? They are the blue and red plastic pipes, not copper.

@ Alex – Glad to hear you had good results from the insulation. You’ll want to wrap those pipes, both hot and cold. It will help in the summer and winter.

Hi Todd,

We just got water in our basement which required us to twear down the finished portion. As sort of expected we found the vapor barrier againste the drywall and the wood studs pressed flush with the bare concrete blcoks. Of course this meant wet insulation and mold behind the wall. Once we solve the water issue (which may be a quick landscaping fix) is it just as prudent and relatively not that much more costly to just tear down the framing and start from scratch or can we use the existing framing and improve on the moisture barrier situation that existed previously? I think I know the answer but anothe ropinion always helps.

@ Peter – Sorry to hear about your water problem.

Depending on the severity of the mold problem you may be able to save some of the framing. I would recommend you move the wall away from the concrete block, install foam insulation, then finish the wall. If the wood is soft, really molded, etc then I’ll throw it out.

Thanks Todd,

I dont thisn k it is all too bad. Ther emay be a corner whenre the water damage seems to have orginated form that needs to be replaced but having got behind the wall, it appears that there is minimal wood damage. Now that we have addressed the mold, I will be tackling the insulation and walls next. Glad I had a chance to read this article and forum.

Todd,

1. I have purchased the 2″ XPS and I am ready to adhere it to the walls. My question is “Do the walls have to be perfectly flat for the foam to do its job as a moisture barriar?” It is a poured foundation, but in some places where the concrete forms joined there is a bit of mismatch which could leave an air gap behind the sheet in certain areas as it over laps these. Or is the tyvek tape and spray foam seal top and bottom going to take care of this problem?

2. Does the XPS sheet have to stop at the top of the concrete or can it go all the way up the top of the top plate? (top plate is flush with the top of the foundation wall, not set back)

Thanks,

Rob

@ Rob –

1. No worries….there are very few if any perfectly smooth walls. Just be sure to seal everything well.

2. The key is to stop it where you can continue it back to the sill plate insulation so that you have a continuous envelope.

Thanks Todd,

2. My PT sill plate and gasket are wider then usual and they come to the edge of the concrete foundation. So you can’t or don’t need to continue back. My question is do I have to stop the XPS at the top of the foundation and seal it to the sill gasket or can I go up higher (like an inch) and seal it directly to the sill plate?

Thanks again,

Rob

I would run it up to the top of the plate. Then I would also cut small pieces to sit on top of the plate all the way back till it hits the rim joist insulation, sealing each joint.

I’m in Southeastern Pennsylvania and plan on using a method like this if my inspector will allow it (big if). I plan on installing 2 inch foam board against the concrete, .5-1 inch gap and then steel stud 2×4 wall with rockwool instulation (roxul AFB or similar) with no other vapor barrier. I have a ‘floating slab’ so I plan to run the 2″ foam board down into that. It isn’t truly part of the sump system and is already partially filled with closed cell back rod (radon system). I plan on removing the fiberglass currently at my rim joist and installing foam board installed with spray foam. My township will require fire blocking (drywall) on the underside of the joist behind the new 2×4 walls. I will be using the Delta FL floor product, so I play on running that under the new 2×4 walls and sealed to the fiber board.

Any issues with this plan overall?

Couple of questions. If the foam board has foil does it go against the concrete (I have read different stories on that)? What should be done on areas where you can’t get to the concrete (i.e. sewer lines run horizontal against them? Is it OK to just run the foam as close to the PVC as possible and then spray foam?

Dave – You are on the right track…even with the sewer lines. I would put the foil towards the finished site…it’s a good radiant barrier.

Thanks. Is there any advantage/disadvantage of using a “waterproofer” (i.e. Drylok, Xypex, etc) on the foundation interior prior to attaching the foam board? Do you recommend a particular product?

Fsbr – Let’s put it this way, it can’t hurt….I’m not sure it will do much if you’re going install the foam board.

What would happen if you only use an interior cement sealing paint without the foam board attached to the foundation wall for a vapor barrier?

Then stud your walls(float,with an air gap)and use a vapor barrier- paper faced insulation to fill the stud wall.

Then after dry walling, seal that wall top to bottom with caulk( to keep moisture from inside the basement getting behind that wall and also protect that wall from leaks that may occur in the future from washers or toilets in the basement)?

Also with the glue on paint,I’m guessing at this one, your glue on paint is only as strong as the paint job itself,if the paint that is stuck to the wall is not all that great with bonding then your glue may not bond that well either. So if the paint will somehow peel off the wall so will your glue that is stuck to the paint. I’ve accidentally gotten spray foam on my cement painted walls(using cement paint) then took that foam off after it dried,easily, with the paint attached to it leaving my wall bare in that spot.

Al – That method won’t really work. One problem will still exist. The concrete will still be cold and allow water vapor to condensate on the surface. I just don’t recommend the approach.

Hey Todd,

Peter G. here, how have you been? Question for you. Building out a finished basement. I did one in Beverly and about year ago, we moved to Marblehead, and now I am doing another.

I’ve built my framing/walls about 8 to 10 inches off the foundation to give room to get behind all the walls. This being the case, do I need to put a vapor barrier between the foundation and isulation when I have about 10 inches of space now between?

Thanks, keep in touch

PJG

Peter – How the heck are you man? Small world! You really do need a vapor barrier. Basements are really tricky due to moisture movement from two directions, finished side and foundation walls. Foam insulation is really the best/most appropriate application in the basement. I’ll send you an email and we can discuss more if you like.

Todd,

I am planning to finish my basement in NJ. I have concrete walls and my contractor plans to use polyethylene sheeting on the wall then frame it using pressure treated lumber and then insulate with R13. I have had some leaks on walls in the past and will have a French drain installed. Is this plan ok or should I insist on first having him install 1 ½ foam board insulation and skip the sheeting.

Thanks

RJ – That plan won’t work and it will lead to mold growth. You’ve got to get foam against the concrete first.

Todd,

If the plastic sheeting is covering the entire wall running straight into the french drain and the framing is not touching the plastic would this still create a problem? I failed to mention he plans to use mold and moisture resistent wall board.

RJ – It still won’t work, the concrete wall will be cold, the plastic will therefore be cold, if/when moisture get’s into the wall cavity and hits the cold plastic it will condensate, once it does that the water will be absorbed in the fiberglass and it’s only a matter of time before mold starts.

Thanks

If we use 2″ of foam board I believe I read it had a R value of 13, 1 1/2″ was about 9. Do I still need to have him use insulation in addition to the foam board or is that enough.

RJ – Just depends on what your local energy code requires.

I’m researching a basement remodel also. I believe that building sciences recommends unfaced foam against the foundation. I haven’t seen an R13 unfaced product but maybe it is out there.

Dave – Facing on the foam isn’t all that important as most of it is either plastic or foil. If the foam has a paper type facing then that’s a problem. Unfaced fiberglass is available at all building supply locations.

Thanks. I was just responding to RJ’s comment about R13 foam. I was referring to unfaced foam not fiberglass. I believe Building Sciences recommends, “2” XPS rigid foam insulation(unfaced) tape all joints”. I can’t say if it makes a difference or not as I haven’t every done it. I believe the R12/R13 foam I have seen is considered faced. Perhaps it doesn’t matter.

Todd

Just a quick follow up

Assuming the local code is ok with the R12 or R13 that I’ll get from the foam board would you recommend addding more or is that enough? I am in NJ.

I also noted that at the bottom of the foam board that hits the floor you recommend to seal it with foam insulation. The bottom of my wall will be a french drain, so do I just cut the foam board even with the floor (and then how do I seal that) or do we need to run the board into the french drain an inch or two?

thanks

RJ – The R value really depends on value/versus comfort after you deal with code. It’s like anything else, you get what you pay for. I would imagine R13 in a NJ basement will be quite comfortable.

As far as your drain, I think I’d leave yours open at the bottom so water can get to the drain if necessary.

Todd… Great article. Thanks for the info. I’ve read through the comments and have a better idea of what I need to do but here’s what I’ve got. I live in Michigan so we have some harsh winters. My house is 60 years. To my knowledge there has never been a water leakage or dampness issue and I have lived here over 2 years. The previous owners finished half of the basement walls with brick, floor to 2″ below the first floor joists. There is a 1″ gap between the brick and concrete wall. I’ve torn down a wall that was dividing the finished side with utility side and now want to finish the rest. I intend on using your methods described here instead of brick, however… The brick stops 3/4 across one of the walls. Do I butt the foam right up to the brick (which would close off the 1″ gap behind the brick) or leave a gap? Must I leave a 1″ air gap between the foam and studs if I use 1.5″ or 2″ foam? Do you have any suggestions for insulating beind the brick or is it even necessary? I was thinking I just need to fill in the 2″ gap above the brick to seal in the air gap. Or do you think that will just trap moisture? I hope you can picture all this. I can send pictures if necessary. Thanks!

Dan – can you send me some photos? todd at frontstepsmedia dot com

Todd,

I’ve been thinking about finishing my basement and my research led me to this website. I have a couple of questions for you.

I plan on putting Drylok on the concrete walls, install INSULPINK on the walls, frame with 2×4 ( with 1″ between INSULPINK and studs), spray foam insulation, mold/moisture resistant drywall, then prime and paint.

1. Will the Drylok help or cause harm to the walls? Someone said to allow the walls to breath and the Drylok was going to harm the walls.

2. Is there a better more cost effective product I can use in place of INSULPINK?

3. Will the spray in foam pay off in the near future and does it help with the prevention of mold and moisture?

Thanks in advance

Robert – Thanks for vising the site. Below are some responses to your questions.

1. Frankly I’m not sure Drylok will benefit you at all considering you’re going to use foam insulation. Drylok will not hurt the concrete regardless of the decision you make.

2. Not sure why you’re using both Insulpink and spray foam?

3. Spray foam will pay off, however, its not likely to pay for itself in just thermal performance quickly. However, the real benefit comes from the fact that foam will not lead to a nasty mold problem.

Todd,

Thanks for the reply.

The idea of using both the insulpink and spray in foam was to strengthen the mold and vapor protection.

Does spray foam insulation get moldy when it comes into contact with water? In other words, if my basement get’s flooded, will I have to pull all the spray foam out and re-insulate like I would with regular insulation?

Thank you

Robert – Foam shouldn’t however i caution you that you should use a closed cell foam that will not absorb water.

Todd,

Thanks for the great article.

The previous owner of my house put up wall frame in the basement in front of the concrete, leaving 1-2in” gap.

And he put pink fiberglass insulation between the stud and cover it with plastic sheet vapor barrier.

After reading your article earlier this year, I went down and checked, water was trapped behind the fiberglass, and many of the bottom plate has rotten.

I was planning to replace the bottom plate and redo the whole insulation this spring with rigid foam glue to the wall as you suggested.

Last week, we got 2 feet of water flooded into the basement! I removed all the fiberglass insulation as they are all wet.

If I glue the rigid foam insulation to the concrete wall, and if I get another 2 feet of water, will there be a problem? Will moisture trap between concrete and rigid foam insulation? Do I have to tear out the insulation to dry it?

I am also worry about moisture coming up from the ground.

If I put up dry wall on the wooden frame, the will be a cavity between the foam insulation and the drywall, and since moisture can come up from the floor, wouldn’t the moisture be trap in the cavity and rotten the wooden frame structure?

Thank you,

Tim

Tim – For starters I wouldn’t recommend finishing a basement that has the chance of 2 feet of flood water. Frankly your money would be better spent trying to fix the flooding issue.

The foam would be fine after a flood. however, the drywall, framing and other products would not fair so well. Sorry for the bad “recommendation”.

Todd,

Thanks, I will not finish the basement now, even the neighbor said they were never flooded for the past 15 yrs.

Instead of completely finish the basement, I just want to glue the wall with rigid foam now. The whole house become very cold now with any insulation in the basement.

The code here require a fire barrier to cover the foam, as the foam will release toxic gas in case of fire, thus, I need the wood frame to put up gypsum board. Any suggestion on how I may do that without wood frame?? Or any other material choice?

I was hoping to semi-finish it: just put up some wall, and rubber mat on the floor like the gym, so the kids can run around and play down in the basement. When I get flood again, I can just bring the mat to outside, and dry the floor and wall with a blower.

Thanks,

Tim

Thanks,

Tim

Tim – A flood every 15 yrs isn’t all that bad I suppose. In that case you could probably frame it and insulate with foam, then install the drywall.

Hi there, thanks for all the great info! I’m insulating the basement as you’ve advised (rigid foam on walls, 2×4 walls, and then batt insulation). My question is regarding the floors….I want to put the rigid foam insulation on the floors as well. (we live in very cold manitoba). Do I insulate the floors first, leave a 1/4″ gap around where the floor meets the wall, then insulate the walls, and then spray foam where the wall meets the floor? And then put a plywood subfloor on top of the floor??

Does that sound right to you??

thanks!

Kendra – That will work fine, you may need to add a Tapcon screw or two to keep the floor tight.

Good Day Todd,

I am very glad I found this website as it has pretty much confirmed what I wanted to do. Of course with any basement there are variations and mine is no different.

I live in Southern Ontario in a 6 year old home that I have been in since it was built. The basement is completely below grade with the exception of the top 12″ or so.

The builder insulated the upper 4ft of the basement wall with a pink batt style insulation which is held to the wall with a vapor barrier. The vapor barrier is sealed to the concrete wall at the bottom with some sort of seal and nailed directly to the concrete. The insulation and barrier extend right up into the joists where they are heavy duty stapled to the joists and flooring on the main level.

My question is can I leave that in place and install the XPS foam on the lower 4 feet of the concrete wall and seal it to the insulation with a thin section of vapor barrier and tuck tape.

I have gone ahead and unstapled the currently installed insulation vapor barrier in a few sections and found no moisture or mold in the insulation behind (either at the top or bottom). In fact the insulation feels brand new. The installer also did an excellent job as all the seals around the joists are excellent.

I understand that the best best choice would be to rip it all down and do XPS all over, but given the addition cost and labor to do so would I be taking a big risk to leave that insulation as is?

Thanks in advance for your advice.

Stuart

Stuart – Sounds like your builder did a great job. If you’re satisfied with the job then I’d leave it. Good luck.

Thanks Todd!

I was hoping you would say that.. It will save me a lot of grief..

This is exactly the same scenario and execution I am planning on doing… And searching for an answer whether this will be acceptable. I am in southern Ontario and most new homes are insulated this way.

This is an amazing reference website and thread. Thanks Todd

Hi Todd!

Thank you for your service. I was so glad to find your website and get definitive direction on properly insulating a basement.

I live in Michigan and am having my previously semi-finished basement redone. I have had some water leakage (cracks and rod holes) that will be sealed before insulating. Here are my questions:

1. Is spray on foam superior to rigid foam (i.e., is it worth the extra cost)?

2. How important is it to place the frame an inch away from the wall, and does the answer differ if I use spray versus rigid foam?

3. About 2/3 of my basement is already framed tight against the wall. Should I remove the frame (especially since I have had water leakage and the bottom plate is not pressure treated nor placed on composite decking material)?

4. I was not planning to drywall the foundation wall of my utility room and narrow storage room. How do I properly insulate these areas? I assume I should not leave them bare even though the outside walls of these rooms will be insulated?

5. Do I need to treat the walls or floor for any possible mold growth before insulating?

6. If I am installing carpet on the floor, how do I properly insulate the floor?

Sorry for so many questions, but I really appreciate your help!

Richard – Thanks for all the compliments. First off I would suggest fixing the leaks and waiting some time to be sure the repairs were effective especially seeing you want to use carpet.

1. Spray foam is definitely superior, it’s just a matter of cost.

2. The gap isn’t all that important when foam is involved, in fact, you can place the framed wall about a 1/2 from the concrete if you want and spray foam the wall in place.

3. This won’t matter if you choose spray foam. Be sure to check the plate for any rot.

4. If the outside walls are insulated you could leave them un-insulated.

5. You should check for mold before you start. If you find it the surfaces should be cleaned.

6. Check out my article on basement floors, http://www.homeconstructionimprovement.com/how-to-insulate-a-concrete-floor/

Good luck.

I am in the beginning stages of finishing a completely unfinishined/bare cement basement in Southwest Michigan. I read your articles on insulation and appreciate the tips, however I haven’t read anything on floors. Can you give me any suggestions on how or if I should go about insulating my cement floor.

Justin – Check out this: http://www.homeconstructionimprovement.com/how-to-insulate-a-concrete-floor/

I am a little confused. You state to install atleast 1.5 inch foam and seal alll joints to create an effective vapor barrier. How does the concrete wall dry up then?

Tariq – Concrete actually will never fully “dry”. In fact, you really don’t want it to. Concrete is created by a chemical reaction between water, cement (calcium and other chemicals), sand and stone. Water gets trapped in the micro-structure of the concrete and continue to react with cement particles for years. Water inside the concrete is actually a good thing! All we’re trying to do is keep the water away from the wall framing materials. I hope that helps.

Thanks for the great information. i’m starting my basement finishing project and am wondering if the fiberglass insulation you recommend installing in the wall cavity is supposed to be kraft faced or not? thanks for any advice.

Tike – It depends. The easiest answer is to read through the comments for several questions/answers that address that question depending on the insulation that you use.

Question,

You say to use spray foam and tape, is there something wrong with using some kind of caulk in the the tongue and grove as well as where the foam meets the floor?

Thanks,

Fred

Fred – Most caulkings don’t interact well with foam. Spray foam from a can works best.

You have lots of great info, hopefully I will explain my situation good enough so you can tell me what I shoul do.

Just bough a house in NY about 1 hr north of NYC,its got a finished basement no water on floor but, the sheetrock gets wet only at bottom.

Behind sheetrock is a foil like material with paper backing, behind that is plastic sheeting, the moisture is on the plastic and the painted concrete blocks, it runs down plastic and gets absorbed into bottom of sheetrock.

Should I remove plastic? If so I need to remove all sheetrock to get to it. If not where should all that trapped moisture go?

Thanks in advance

Lou

Lou – This is a classic example of what happens when moist air hits a cold foundation wall. The best solution is to remove everything and insulate the walls properly with foam (spray or board). You need both an insulation and vapor barrier to stop this problem. You could remove the lower couple inches of drywall but frankly the water/moisture is going to cause other problems. You’re better off fixing this situation properly.

We’re finishing our basement, and we have a vapor barrier installed against the concrete walls as advised. However, we’re using a foil-based radiant barrier instead of foam.

Does it matter then if we use faced or unfaced insulation between the studs?

Alex – In my opinion you’re asking for trouble and here’s why.

1. That foil faced radiant barrier is only a radiant barrier. It will still transfer the cold temperatures of the concrete.

2. If any moist, damp air passes through the fiberglass and contacts the cold foil it will condensate.

I would not use this method.

Hi,

Very interesting page.

We just moved into a house this winter. Now, with this weather, I start smelling something like water vapor(this what I think).This smell It is only in living and kitchen. This house it is not new. The basement it is finished but in an old stile like ’70 or ’80 with wood panels and carpet and no insulation against the walls. It is also the coldest place in the house.

What shall I do to get rid off this smell in the living and kitchen?

Do you have an idea what the cause could be?

Thank you!

Florin – Not sure what you’re smelling. Water vapor can’t really have a smell. Maybe you’re smelling mildew? Could be old carpets, mold, mildew or a number of things.

Hello, I am in need of some help. My wife & I live in a new home(2yrs) in Spruce Pine, NC. Because of the moisture problems of building a below grade basement, we built an above grade block basement with 8 inch hollow block walls, so our house actually looks like a split level. I have sealed the walls with a water-proofer & have no problems with water intrusion, the only problem we had this winter was that if the basement temperature was allowed to drop to 55 degrees the walls would start sweating and was actually causing some problems. The reason I have come to gather that it is sweating is because after we applied heat to this space, about 62 degrees the sweating stopped & the walls were dry. So now my question is what can I use to insulate these walls to make a living space & then not have to worry about the walls sweating?

Thanks for your help & God Bless

Jason – I would suggest insulating the walls with 1-1/2″ to 2″ of closed cell foam board, seams taped, then framing a wall in front of them. We have several articles on this site about that topic. The insulation will keep the walls from getting cold on the inside which is why you’re having sweating problems. The nice thing about foam board is it’s a very friendly DIY product. Good luck.

I am about to start my basement and have been going back and forth on whether to use a 4mil – 6mil vapor barrier plastic on the walls or use something from HD that is a 3/8″ pink insulation board from Dow. I was then going to frame and insulate the walls with faced insulation.

As a follow up to my posting, I read on the Building Science site that using 3/4 xps on the foundation walls along with 3.5″ fiberglass batt insulation would work well as long as humidity was kept low during the summer.

Does that include faced and unfaced batts?

Would 3/8 xps work?

Can I leave a gap between the xps and the studed wall?

Julius – Thanks for visiting the site. 3/8 xps really won’t cut it and frankly 3/4″ is marginal in my opinion. The foam board serves two purposes, first off if it’s thick enough (and most people argue about this but i say 1-1/2″ minimum) it will act as a vapor barrier so long as it’s truly closed cell foam, secondly the thickness creates a thermal break so that any damp air from the “warm” side that migrates towards the concrete will not hit a cold surface and condensate. Make sense?

I live in Pgh and purchased a home with a finished basement. Noticed some leaks under baseboard and had interior french drains installed. The basement is heated by furnace vent and gas stove and Air Conditioned along with dehumidifier. I want to reinstall the wood paneling that was removed to have french drains installed. Do I need to do the vapor barrier and insulation? I’d like to eliminate those to avoid future moisture problems. Thanks.

Carolyn – Where abouts do you live? Where is Pgh? If you live in a cold climate I would highly recommend that you properly insulate the walls. I suggest you consider using foam board (which we’ve written about quite a bit on this site) as an alternative that’s DIY friendly.

Thanks Todd – Pgh is Pittsburgh PA. I was leaning towards using the foam board, until the interior french drains were installed and the drain contractor said to attach 6 mil plastic to hang over concrete block wall 1/2″ into drain “trench.” My thinking was that since the basement is heated and cooled that condensation would be eliminated and the air flow between the block wall (without vapor barrier) and wood paneling (or drywall) would be beneficial.

Carolyn – The problem is this. If you heat the space in the winter, you have warm, damp air floating around. That air will get behind the paneling and come in contact with a very cold foundation wall. That wall will be well enough below the dew point for the warm damp air to condensate. I would highly recommend installing a minimum of 1-1/2 inches of closed cell foam on those walls prior to installing the paneling.

Thanks Todd. That does make sense. After much review, my question now is which is better, extruded polystyrene or polyisocyanurate for basement walls?

Julius – I like using xps, it’s cheaper and does what it needs to do. Polyiso is better suited for exterior wall applications where you can also take advantage of the foil faced covering for radiant.

Hello Todd, Just wondering if it makes any difference if the concrete foundation walls are exposed to the air outside or if the foundation is below grade. My house in Missouri has both, with the back wall of the house being a walkout basement with framed walls but the other three walls being concrete. The side walls have the grade traveling up the wall until it is fully below grade, and the front wall being completely below grade. I want to use foam board but am not sure if the exposure makes any difference as to the thickness of foam required. Thank You.

Mark – It doesn’t really matter that much. I always size the foam based on worst case, the exposed concrete. I say pick a thickness and use it everywhere.

Todd,

Thanks for the basement insulation info. I am in the planning stages of finishing my basement and wanted to know your thoughts on the following:

I originally had planned to put a 3 mil vapor barrier directly against the basement walls (painted concrete) and then frame while leaving a gap between the frame and basement wall and insulate with fiberglass batts. The rationale was the 3 mil vapor barrier would serve to protect the framing from any water intrusion (i.e such as the vapor given off from the walls as in your first figure). After reading your website I realized that this approach isn’t the best.

It seems that the key here is to separate the “interior” (i.e. the conditioned air in the finished basement) from the “exterior” (i.e. the basement walls and their associated moisture vapor) as much as possible.

That separation needs to be done both physically (vapor barrier) and thermally, something the vapor barrier alone doesn’t do. Without a thermal barrier there will be condensation on the interior side of the vapor barrier which can lead to problems.

Would it be advisable to put a vapor barrier directly against the basement wall, then put foam board against the vapor barrier and then frame and insulate as described? Would a second vapor barrier over the fiberglass and behind the sheetrock be a good idea?

Thanks in advance for your thoughts!

Jason N

S.E. Michigan

Jason – Glad you read it and understand it!! It’s a complicated thing to wrap your head around and you seem to have picked up on it.

Frankly the vapor barrier on the wall prior to foam won’t buy you much unless you’re going to use a layer of foam less than 1-1/2″. If you properly install a layer of at least 1-1/2″ of closed cell foam, tape all the seems, seal the edges with foam (spray foam in a can) then you’ve created a thermal and vapor barrier.

I prefer to then use a kraft faced insulation as it tends to breath better than poly. Also, if you can afford it, you can just use 2″ or more of foam and skip the fiberglass all together.

Todd i have a basement with cinder block walls. these walls are damp about 2 to 3 blocks up in some places. Also in the corners it goes higher in 2 corners 3 to 5 blocks high.Also i think i have an old french drain system.I say this because i found clay pipe about 4in below the footing.This was found while digging around the sewer outlet pipe. This house was built in 1956.I am going to have a new french drain installed with 2 new sump pumps.I am then going to finish the basement.My question is can i install riged foam about 2in from the block walls then frame it out?I figure this will let some air movement between the block and foam and keep it somewhat dry and stop mold.

Mark – Water won’t hurt the cinder blocks a bit. All concrete (which is the main material in blocks) contains water in the pore structure for years so the water is not a problem. Water also won’t cause a problem with the foam. That’s why we attach the foam to concrete and block walls. The foam will keep moisture from entering the finished space and keep it against the block/concrete wall.

It’s pretty hard to come up with a way to attach the foam 2 inches off the wall and keep it in place.

Todd,

I have a trench around the perimeter of my basement leading to a sump pump. I’ve lived in the house for two years and have never had any water problems thus far. How should I go about insulating around the trench?

Matt – I would just bring the insulation down to the top of it. Are you going to frame a wall?

Todd- Yes I plan on framing the walls. So with 1.5 inches of foam should I space the wall an additional 1.5 inches away from the foam? I believe the trench is approximately 3 inches wide.

Matt – Couple of options. You could do just that or you could install a piece of composite decking down first over the 1-1/2 of remaining drain, then frame on top of that.

Hi

I live in a colder northern part of Canada and I have a cinder block foundation that had many leaks and problems. To this point I have done the following. Dug up the outside of the whole foundation and repaired damages areas. Applied 2 coats of sealer around the footing and up 36 inches. I than installed Delta MS house wrap around the whole foundation right down to the footing. On the inside I have installed 1″ foam board and taped with tuck tape. I have the 2×4 framing up around 1″ from the foam board. My quetion is should I also put 6ML vapour barrier or just install the fiberglass insulation, than drywall.

Also any comments on what I have done to this point, weather it should be enough etc. would be appreciated.

Carl – Sounds like you’ve done a great job so far! Congratulations for fixing the outside problems first!

1″ of foam isn’t really enough to act as an effective vapor barrier on the concrete side. What that means is during the warm summer months moisture in the foundation could possibly permeate through the foam and enter the stud bay with the fiberglass. Because of that you’re going to want to use a vapor retarder and not a vapor barrier. 6 MIL poly will not let it breath enough. There are quite a few vapor retarder products on the market now that should work well. Ask you local building supplier.

The rest of it looks great.

Good luck.

I am currently in the middle of refinishing a finished basement. The house was built in the 50’s. It is located in central new jersey so summers are hot and winters are cold. The problem I have is that the wall studs were built up on the cement basement wall. I can not get behind the studs. First thing I was going to do is drylock the walls, then buy R-15 (used in this area), and install the insulation backwards, so the plastic vapor barrier is touching the drylocked cement wall. Then finishing with Drywall.

There is no signs of water damage. I do not think water is getting into the basement, however the floor does sweat when the air difference is great between the basement and the rest of the house. I am trying to for the cheapest solution to sweating floors.

Thank you in advance for your answer.

Ryan

Ryan – Your solution only solves half the problem. It will keep moisture from the concrete wall from getting to the insulation. However, it won’t stop moisture from the finished basement from entering the stud cavity, passing through the insulation, hitting the cold plastic and condensating inside the wall. What you need is both a vapor barrier and insulation at the concrete interface to stop both processes.

Todd,

Thank you…one last question (maybe)

I am not worried about the temperature of the basement. It is cool in the summers and warm in the winters. I am only worried about stopping the tile sweating. I would like to put a carpet down. Will insulating the walls help with the floor sweating. If not, I might just make the it easier and not insulate at all. Will Drylocking the walls, and running a dehumidifier, with the AC/Heat on upstairs stop the sweating enough that I do not need to worry about mold going under the carpet?

Ryan – It’s very hard to say. Sweating is based on dew point. While you might not be concerned about the walls what I’m pointing out is likely to happen. Warm in the winter inside the finished space can and will cause a problem as you described. Warm, moist air from the finished space, passes past the insulation and hits the cool/cold plastic that sits against the concrete causing condensation.

In the summer the opposite happens.

Insulating the walls will make a drastic change in your basement. Are you sure the floor is sweating or is moisture coming up through the slab? If a vapor barrier was not used that is a real possibility.

Drylocking walls won’t necessarily stop the situation on your floor. Dehumidifiers will help some but i’d be very cautious about carpet in a basement that clearly has damp/moist air problems.

Todd,

I’m planning on using 2″ square edge Dow foam (T&G was twice the price) insulation adhered to the block wall with adhesive and taped along the seams. I plan to leave at least a 1-1/2″ gap between the foam and the wall. I have extensive 3″ DWV pipe running along the walls.

1. Should I cut a channel for the 3″ DWV and fill that channel with spray foam?

2.

a. Since I’ll be paying only $18 a panel for the 2″ foam, should I place the rigid foam in the 3.5″ stud cavity, i.e.,

block wall–> 2″ XPS foam–> 1-1/2″+ gap–> 2×4 framing (rigid foam within the stud cavity with the foam pushed against the drywall, and a 1-1/2″ gap to the rear edge of the framing)?

b. Instead of placing rigid foam in the stud cavity, could I glue some 2″ and 1″ together against the wall with the seams staggered?

Thanks,

Ben

Allow me to clarify 2b

Can I glue 2″ and 1″ rigid foam panels together on the block wall and leave, leaving the stud cavity empty?

Ben – Square edge is fine, the T&G just makes it a bit easier during installation but it’s not necessary.

1. Not sure exactly what you mean. Are the pipes tight against the block wall? and therefore you’ve planning on leaving a gap at pipes and sealing along the edges?

2a. Depending on where you live 2″ of XPS is a pretty good insulation layer and you may not need additional insulation for the stud cavity. Having said that using another layer in the stud cavity is sure better than using fiberglass in there.

2b. This method would also work nicely and create an even better vapor barrier.

Thanks, Todd!

The pipes in some places are pretty tight to the wall. I was going to use a hot knife or something to shape the panels to fit around the pipes. What do you think about this technique? Should I spray some expanding foam behind them?

I still have to run 3″ drain pipe along one wall, but I would really like to keep that pipe pretty close to the wall. Would cutting the panels and sealing the gap between the block and the pipe with foam significantly compromise the barrier properties of the foam panels?

One more question: how critical is the gap between the foam and the framing members in the wall?

Thanks again!

Ben – If you can fit the foam tight and foam the edges that should work pretty well to lock out water vapor. The gap isn’t critical if you don’t plan on using fiberglass.

Todd do i have to use blue foam on my damp basement walls,or can i use another type then stud up aginst it and then use batt with a vapor barrer.I have seen pink,green,foil backed both sides and white,and the type they put behind siding,but no blue.Also i was told i could tar the inside wall then put plastic on the tar?.

Mark – The color doesn’t matter, pink and blue are typically XPS, closed cell foam. Foil faced is typically polyiso insulation, that works too. Be careful of white as it’s typically open cell foam board. I’d avoid putting tar inside your home. Good luck.

Todd,

Thanks for providing a wealth of info here. Back in March for the first time, I had some water seep into my basement which I refinished 15 years ago when I purchased the house in Queens, NY. The water entered at the bottom of the poured concrete wall where it meets the slab in a small area after a 3″ rain storm. I removed the drywall, 6 mil vapor barrier and insulation from between the studs which does not have any mold. However, some of the paint / moisture proofer applied to the concrete has spalled off in some areas near the bottom of the wall and the bottom plate, which I removed had some mold. The studs are about 1/4″ from the concrete which were in place with wood paneling from previous owner. I was going to cut 1′ off the bottom of the studs, install trex deck as you recommended, install pressure treated plate on top of it and splice in studs. Is it necessary to remove everything and install 1.5″ foam unto concrete wall and reframe and insulate? Do you have any recommendations to treat the seam to prevent water from penetrating again?

Thanks, Peter

Peter – Sounds like you’ve been quite fortunate with a relatively dry basement. 15 years is a good run!

First off the water issue. Sounds like this was caused by a very rare large rain event. I’d say the best approach is to evaluate the outside of the house, gutters working? grade sloped away? any cracks in the foundation? settling? etc. Deal with any issues you may have outside.

Sealing inside at the base of the wall is probably a futile attempt but I suppose it doesn’t hurt to try and seal that joint with a good quality masonry patching materials.

Why are you removing the lower foot? Rot? Mold? Damage? If there’s no damage that may not be necessary. The bigger issue is whether to leave the walls in their current position or to move them. You could install foam board between studs in lieu of fiberglass. This won’t create a tight barrier but it seems as though your moisture problem isn’t too bad.

Or you could cut free the walls, move them forward, add a layer of foam and go from there.

Hope this helps.

Todd what is the thinest rigid foam i can use over my damp walls since i am also going to add batt.

Mark – you really need a minimum of 1-1/2 to create a vapor barrier.

Todd,

Thank you for the great articles. I’ve read both this and your basement floor finishing article in preparation for my basement repair (in southern New England.)

We have had a few intrusions of runoff during bad storms recently, and as a result I need to repair/replace at least the bottom, below grade half of our finished basement walls. I would like to avoid whole-wall replacement due to lots of soffits and trim up at our basement ceiling which would add complication/cost to the project. We have never seen runoff damage or condensation higher than about 12″ off the floor, and I’ve verified there is no seepage on the bottom 4′ of wall with the aluminum foil test.